- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-04-19 Origin: Site

HARTING Technology Group: How connectors drive sustainability

Sustainability has undoubtedly become one of the focus issues in modern industrial manufacturing. This requires not only the materials used to be sustainable, but also the production processes. Sustainable processes require not only efficiency but also resource and cost savings by, for example, avoiding machine downtime and reducing downtime. Additionally, employee hours are one of the valuable resources of a production facility, and efficient maintenance and installation are key to ensuring maximum utilization of this resource.

Connectors play an important role in creating such sustainable production processes. HARTING focuses on more than just their ability to quickly connect or disconnect equipment or attachments. In fact, modern connectors provide production workers with a safe and precise way to connect, especially in modular systems that often need to be reconfigured. Accurate connections not only help save energy, they also save time.

SmEC – HARTING’s connector concept for modular machines and systems

One of the most important functions provided by a connector is to provide a signal indication of mating status. Mating status involves various parameters depending on the application and connector. The docking status usually provides the following key information:

Has the connector been properly plugged into the corresponding mating connector?

Does the connector make a complete electrical connection?

Does the connector achieve complete mechanical locking?

Is the connector electrically overloaded?

Are the environmental parameters (such as temperature, humidity, etc.) within the allowable range?

The plugging status often provides prompts to the operator through LEDs, light rings or sounds. In the simplest case, a red/green indication is enough to let the operator know if a fault has occurred. Modern full-color LEDs can also indicate more states such as voltage through different flashing patterns or dynamic effects. In addition to these intuitive visual and audible cues, the digital interface can send more detailed data to the control center. The SmEC (Smart Electrical Connector, Figure 1) launched by Harting Technology Group can transmit data through MQTT or OPC-UA PubSub. The data is provided in JSON format, which any controller can receive and process. In addition, the Asset Administration Shell can also provide real-time data from the connector to achieve digital twins.

In addition to indicating mating status, SmEC also has a built-in locking mechanism to avoid accidental connector disengagement. This not only ensures that components are not damaged, but also ensures the safety of operators. The connector can only be disconnected after power has been removed and the lock has been released. To this end, SmEC integrates voltage and current measurement functions and monitors the connected devices. In this way, real-time carbon footprints can be calculated based on energy consumption data.

Figure 1. Technology Demonstration---Smart Electrical Connector (SmEC) with status display and identification functions

Data diode – connector concept from HARTING for vandal protection

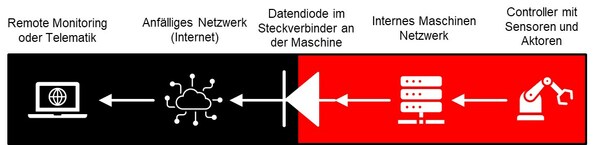

Carbon footprint measurement can also be easily implemented on older machines. Data diodes protect measuring devices such as smart electrical connectors from damage (Figure 2) because they only allow data signals to be transmitted in one direction. This feature ensures that data can be transferred from a protected network to an unprotected network, such as to a control panel, so that the protected network is not vulnerable to attack. To achieve this, HARTING has developed data diodes specifically for connectors. It supports data rates up to 1Gbit/s and is able to transmit common IoT protocols such as OPC-UA, MQTT or Modbus-TCP. The data diode is a physical hardware composed of a laser diode at the transmitting end and a photosensitive diode at the receiving end, ensuring that data does not flow in the reverse direction.

Figure 2. Function implemented by the data diode in the connector

Smart ix - HARTING’s connector concept for small connectors with identification capabilities

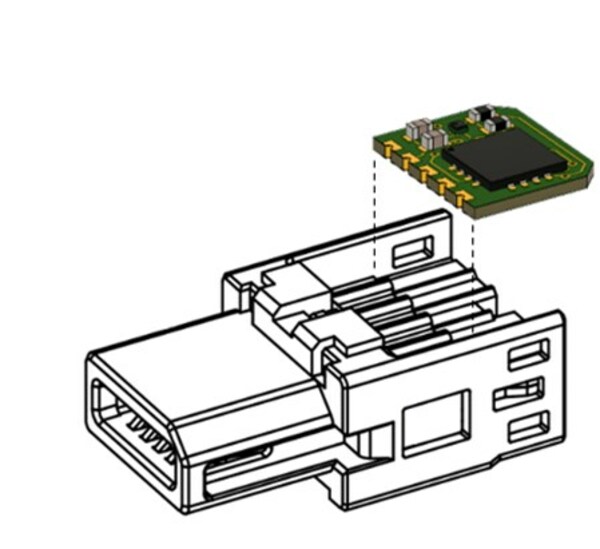

In order to ensure that a connector is correctly inserted into the corresponding mating connector, it needs to be able to identify the connector. At the most basic level, this can be accomplished by adding electrical contacts as coding pins. Unlike mechanical coding, this method allows the machine control system to determine which accessory is currently inserted. But this approach quickly becomes limiting in large, flexible systems. In addition, the coding pins used for electrical coding consume a large number of contacts. A more ideal approach would be to use a bus system and a small microcontroller to identify the connector, or alternatively through near field communication (NFC). This involves assigning each connector a unique ID that corresponds to the corresponding component (such as an accessory or tool). This approach also works with very small connectors, as shown in Harting’s Smart ix (Figure 3). Smart ix is a small 10-pole connector with an integrated microcontroller inside. Through the microcontroller, accurate identification can be achieved. The ID is used for unit or machine control to ensure the correct link is established with connected components. In this way, even simple components such as light fixtures, door contacts or analog sensors can be accurately identified. Control signals tell the user whether the component is correctly plugged into the corresponding port.

Han Protect - Han® 3A - HARTING's connector concept for simplified repair processes

During the production process, unnecessary downtime often occurs due to the temporary unavailability of the required professionals on site. For example, only professionally trained staff can replace a faulty fuse. Since the fuse is usually located inside the control cabinet, it is difficult for others to replace it. When the fuse is integrated into the connector, such as Han Protect (Figure 4), the fuse can be easily replaced from the outside. Since the connector must be disconnected when replacing the fuse, even non-experts can easily replace it under low voltage conditions. This effectively shortens repair times and reduces downtime, which has a profoundly positive impact on resource management.

Figure 3: HARTING Smart ix industrial - with identification of small connectors

Figure 4. Han Protect - Han® 3A connector with built-in fuse

The HARTING Technology Group continues to launch innovative solutions in the field of connection technology and is committed to enhancing the sustainability of industrial production. The concept of smart connectors proposed in this article will be demonstrated at the technology demonstrator at the 2023 International Industrial Automation and Components Show (SPS) in Nuremberg, Germany.

About HARTING:

HARTING Technology Group is the world's leading supplier of industrial connection technology. HARTING serves the global market with 6 R&D bases, 14 production plants, 44 sales and distribution companies, and approximately 6,500 employees. HARTING's connectivity solutions are used to transmit data, signals and power in numerous industrial sectors, including transportation, electromobility, renewable energy generation, automation and mechanical and plant engineering. As a family-owned company, HARTING achieved a turnover of 1.059 billion euros in 2021/22.